Vibration isolator

Yuanxing Group's vibration reduction technology and products will be first applied in the field of urban rail transit, and then vigorously promoted and used in areas such as passenger dedicated lines and high-speed railways; It can also be applied in fields with high seismic requirements such as hospitals, kindergartens, cultural relics buildings, nuclear power plants, etc., and has broad application prospects.

Stable structure with good vibration reduction effect

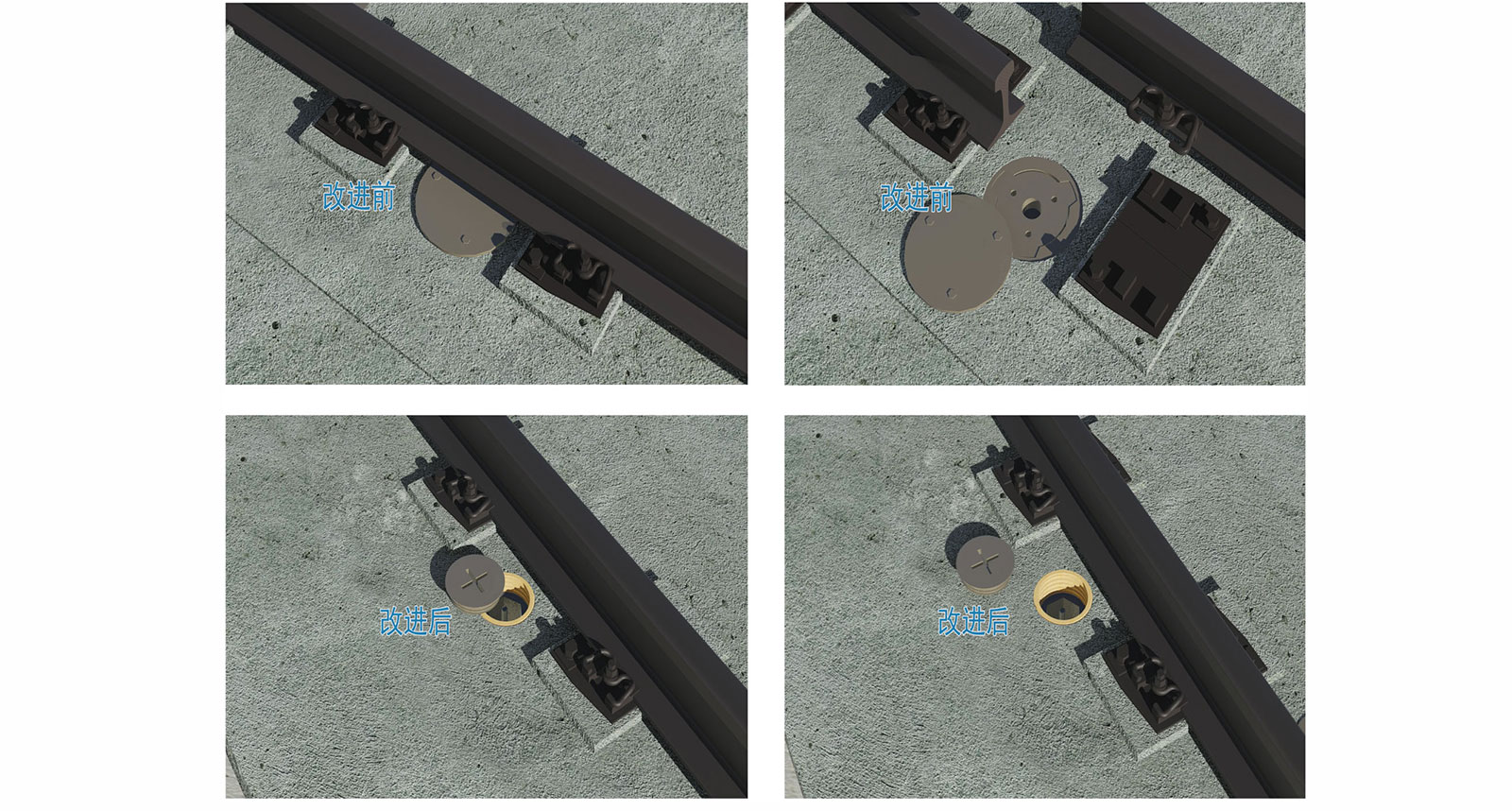

The technology of replacing inner sleeves without sawing or pulling out rails

High performance vibration isolators can ensure that they are placed on the outer side of the track bottom within the safe driving limit of the train, without the need for rail shifting or sawing during lifting maintenance, making construction convenient and shortening the construction period.

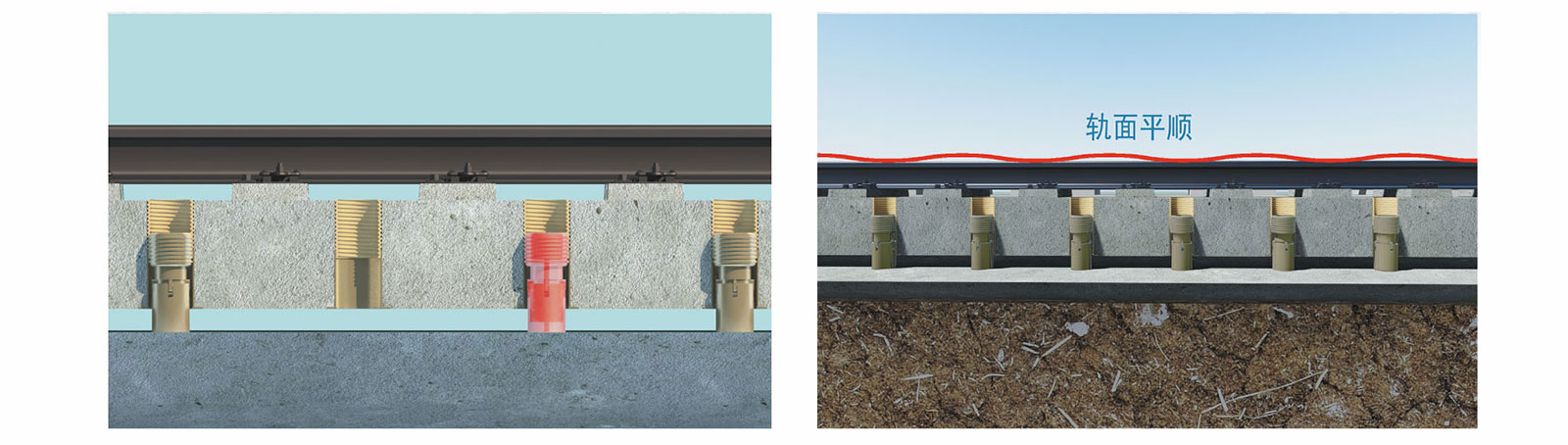

The stepless adjustment of the height ensures that the floating plate is subjected to uniform force and the rail surface is smooth

The high-performance isolator adopts a threaded structure to achieve stepless height adjustment, completely eliminating many drawbacks caused by the traditional steel spring isolator using a gasket structure. Ensure the accuracy of the lifting height through the scale on the shock absorber. Eliminated the situation of empty suspension of shock absorbers, making the rail surface smooth along the line direction, thereby reducing low-frequency noise

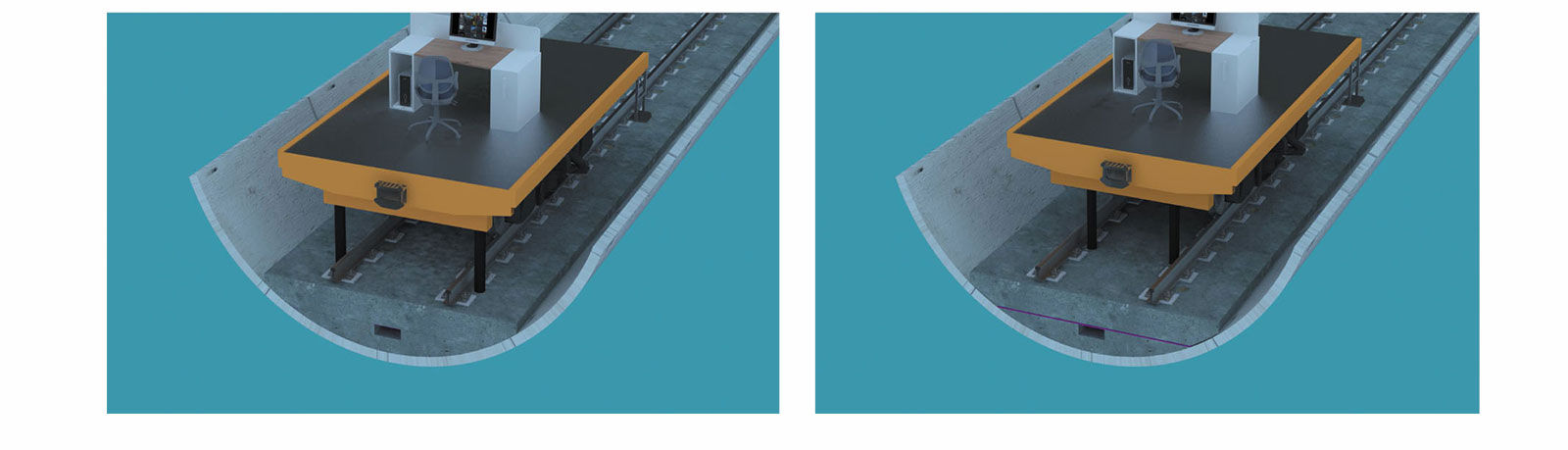

Convenient construction, operation, and maintenance of high-performance vibration isolator floating plates

After the tunnel is completed, the settlement of the foundation will cause local settlement of the tunnel. High performance vibration dampers adjust the height of the track structure by twisting the inner sleeve, which is easy to construct, shortens the construction time, and has uniform stiffness, so there will be no shaking when trains pass through.

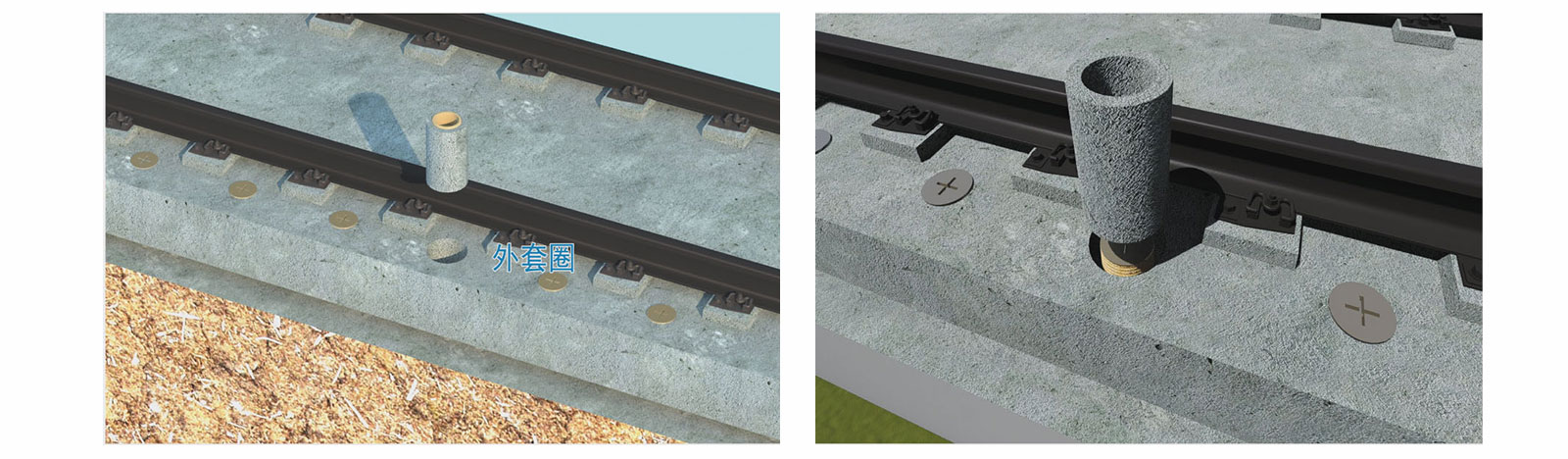

Replaceable outer sleeve design increases the service life of the floating board

When designing the threaded structure, consideration was given to the convenience of future maintenance and installation of shock absorbers, and when designing the outer ring, nylon glass fiber reinforced polyamide 66 was specifically selected. When replacing the outer ring, simply cut open the nylon sleeve and take it out. Use a concrete corer to remove the damaged concrete layer, put in a new ring, and pour it again.

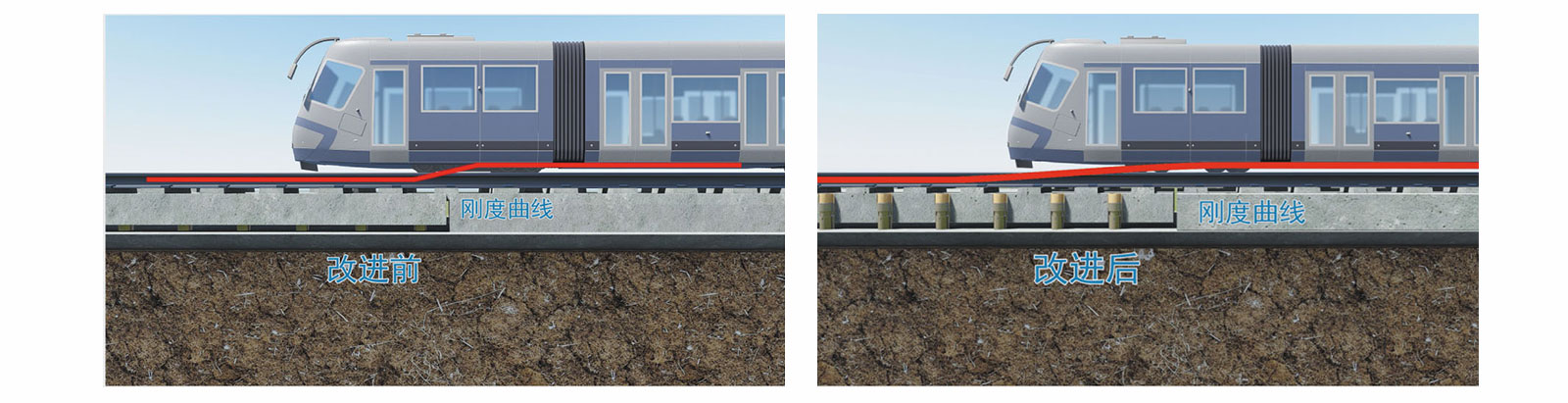

Stepless stiffness transition section technology to reduce wave wear

The stepless stiffness transition section technology was achieved through a specially designed structure in the transition section. After repeated calculations, the stiffness of the final transition section changed from a step like mutation to a smooth transition. This effectively solves the problem of rail corrugation in the transition section.

Intelligent lifting operation to ensure lifting quality

The lifting method of high-performance vibration isolators can be adopted according to different working conditions, using different lifting methods: manual lifting, mechanical lifting, and intelligent equipment lifting to ensure the quality of lifting.

86-510-87131111

86-510-87138713

jsyxep@163.com

Baihe industrial park, Xinjie town, Yixing city, Jiangsu province

Mobile terminal

Focus on applets